410customs

Idahome

Joined: Wed May 2nd, 2018

Posts: 2165

Name: Jamie ... Occupation: Elevator Design Worlds Tallest Buildings ... Interests: Ranger Based Vehicles and OFFROAD ...

Reputation Points: 2165

|

I wish I never rotated the camera, but hey you want to talk about wrecked nerves each and every time I do this there is many sleepless nights and nervous heart pounding hours that lead up to that moment, I waited for the neighbors to come over so they could see the progress and help me turn the key.......before we even attempted to start the truck there was much work involved. Many final checks, then fluids, then finally time to bump the key...will the starter turn? Will the engine fire? Will there be leaks? Did Jasper build the 306 correctly? all of these things lead up to this one moment where you find out if you are worth your salt......

I remember a few years back I saw a video on Youtube "Ranger 5.0 done right" and there were MANY things in that short video that I spotted that were indeed not done properly....so here we are

Now lets re cap all the final work that was done to get this sucker running........

First up the shop dogs (Ranger and Ace) are chomping at the bit to hear this baby run

The 300K battery cables have seen better days, this won't cut it here in my shop so we had to fix them up. All of my battery cables get copper lugs and marine terminals. This truck is no different.

What we are dealing with

To quote Post Malone "Better now"

Hydraulic crimp tool, me likey

end result

Don't forget the anti corrosion spray

Now you guys should take note, the one large ground wire comes from the 5.0, the other was ADDED, it feeds the radiator core support to act as the main body ground.

The two large power wires, one is the starter feed, the other is the PJB feed, the small power wire is for the led bar relay

Now that is all cleaned up we can move forward. Battery was put on trickle charge, time to move into the interior

Now 2000 Rangers came with PATS, in fact 99 was the first year of PATS in the Ranger. So all I had to do was remove the v6 pats module and ignition tumbler and replace with our v8 stuff

I was provided with the v8 pats module, key and ignition tumbler and also a halo. You do not have to swap halo's as all they do is read the key

If the key matches the pats module which matches the PCM your truck will be happy

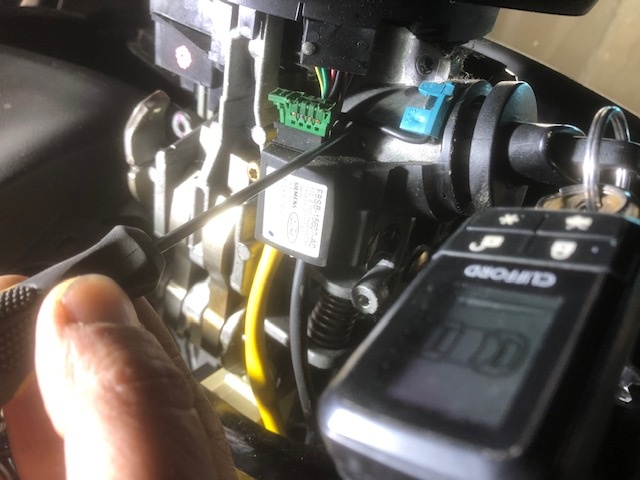

PATS module is located behind the pass airbag, v6 module remove, v8 module plugged in

To change out ignition tumbler and key you need to turn the key to the run position and using awl push in the check ball

Tumbler slides out

install v8 stuff

That's it, when doing 2000 Ranger to 2000 Explorer, PATS is done.

Two paths going forward we can use our Snap on Star commander to program some keys so the original v6 key that fits the doors can be made to work the v8 pats, or we can swap the door lock cylinder to match the new v8 key. I will likely swap the door lock cylinders since they were provided to me AND I am much faster at doing doors them messing with the star commander (on loan from friend Brett) Either way the same key that works the ignition will fit the doors, as if Ford built a 5.0 Ranger.

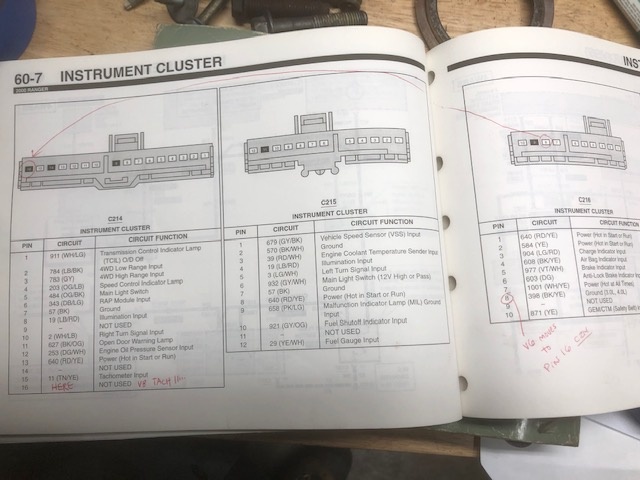

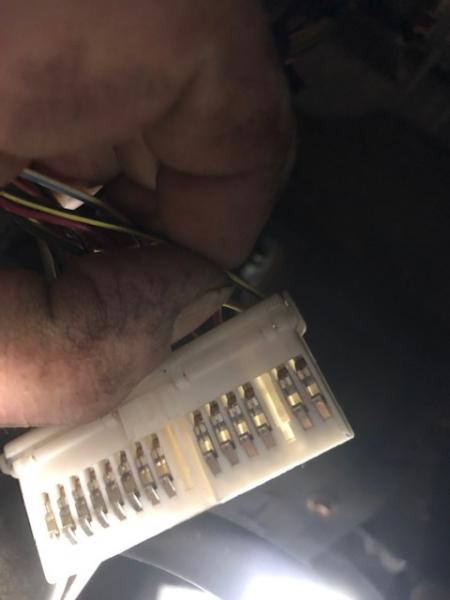

Now the tachometer ground wire needs to move positions. For a v6 truck the wire is in one spot, for the v8 we need it to be in another

Instrument cluster pulled, wire moved

This truck uses a silver cluster from a 03+

Yes I cleaned up the 301K miles worth of debris under the column shrouds

Tachometer now reads for a v8

Time to hook up the battery and scanner and talk to our PCM, check for a properly operating THEFT light

Did some onboard diagnostics and system checks, all modules present and all systems are GO

Now is when the heart starts pumping.........time for fluids and final checks

Added 5 quarts of Amsoil engine 30W break in oil to the crankcase

4 quarts of Amsoil ATF, Mercon V compatible, into the transmission. Do not put more then 4-5 quarts in now or it will spill out...... remember there is also 1 quart in the converter. The system will hold between 10-14 quarts depending on the size of your coolers and how much atf/test fluid is still in the 4r70w

The rest of the mercon V will go in once the truck is running and we have a chance to shift the trans through the gears

Jasper reman engines have been pre run there is no real need to prime the oil pump on a pre run engine.

Otherwise I would remove coil pack tripod and cam synchronizer, I then have a flexible drive for my drill motor that fits the oil pump shaft perfectly. Any time we do a fresh engine assembly we would need to prime the oil pump...not here

Added 4 gallons of Amsoil 50/50 ready to go coolant, the red stuff (makes me crave koolaid for some reason....)

All the while checking the clean shop floor for any signs of leaks

The 4406 transfer case was drained one more time (to get any residual) and then filled with regular Mercon III/Dexron ATF

These t cases use MERCON III do NOT fill with merc V or synthetic....too slippery. Ford says no Mercon V in t cases.

Had to replace one of the t case fill plugs, looks like this one was hit with a punch at some point

Fill plugs get thread sealant

After all of this we finally turned the key and she came to life

Next up is the rear axle swap, this truck is getting a 31 spline 8.8 from an Explorer. The axle just came back from a local gear shop getting its new Eaton posi trac, Ford racing 4.10 ring and pinion, and all new bearings and seals. A new HD diff cover was added as were brand new backing plates and E brake assemblies. These parts were purchased from East Coast Gear Supply, one of my fav shops to do business with!

Driveshaft still needs cleaned up and paint, also new Spicer U joints. This is the 410Customs rear d shaft built from a shortened 5.4 F150 unit

The axle got a little muddy coming home from the diff shop :)

Don't worry it will get cleaned up.

I am about to weld up the Ranger style spring perches and shock mounts so this sucker can go under our Ranger

Next video she will be driving :)

____________________

I build custom RBV, specializing in drivetrain conversions, wiring, suspension and complete custom trucks

|

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6