| PM | Quote | Reply | Full Topic |

Idahome

Joined: Wed May 2nd, 2018

Posts: 2165

Status:

Offline

Reputation:

Reputation Points: $user_rep

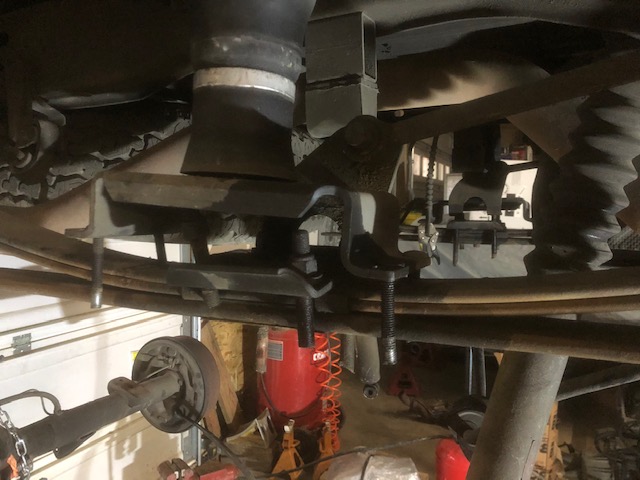

prepping to pull 28 spline 8.8, this is the only use I have ever found for the two "notches" in the bottom of the metal diff cover

now that the fluid is drained we can support the axle and truck, unbolt the shocks, sway bar, U bolts. cut the ranger E brake cables, and cut the brake line after pinching it with some vise grips

One thing I ALWAYS see on these lifted rangers is the rear soft brake line is way tight at full suspension droop.

Easy fix?

Simply bend the upper bracket carefully down, before:

After:

now plenty of slack

and she's out

Oh yeah I cut the U bolts also.... we are using new ones that fit the large 31 spline 8.8 tubes

Time to fab up the exhaust

Here we are using a Borla Pro Xs series stainless muffler with dual 2.5" inlets and a single out

So aft of the stock primary cat converters and downpipes I used some small bits from the stock explorer exhaust to get things started.

Followed by two very long 2.5" tubes, the lower tube is perfectly straight no bends, the "upper" tube has slight bends in an effort to clear the gas tank support crossmember and for perfect muffler placement.

I made the system bolt in completely, the entire exhaust in this truck can be on the ground if you loose 8 bolts, one clamp and 3 hangers.

Much time was spent mocking it up, then it was removed and final welded.

I cannot WAIT to hear this Borla muffler with these long straight pipes

same height as gas tank skid, similar height as factory exhaust

two new gaskets at the flanges

think those welds are penetrating? :)

stickers were removed with "mr heat" gun, I love that thing

I HATE stickers on exhaust tubes, what a PITA!!!!! LOL

Heat gun and plastic scraper made short work of them

Next onto the front driveshaft

all I have to do is swap the centering yoke on this gen I front shaft to the 4406 style flange mount, replace some U joints and we have ourselves a bolt in DOUBLE CARDAN shaft!!!!!!!

back at it again tomorrow...this time with a test drive in mind, I wonder if I will be able to sleep

____________________

I build custom RBV, specializing in drivetrain conversions, wiring, suspension and complete custom trucks