12° North Industries

SITE SPONSOR

Joined: Thu Nov 23rd, 2017

Posts: 389

Name: Occupation: Vehicle Upfitter ... Interests: The great outdoors, nature, back to basics ...

Reputation Points: 389

|

MaDMaXX wrote: Thanks, Under.

So, i understand the centric part and as i said earlier, i have felt the wheels "locate" when tightening them down, i have to assume that all load bearing responsibility on the Rangers with stock wheels, is on the studs?

This being the case, whilst the hug is there and relatively tight to the stock wheels at least, there is no load on it?

I asked earlier if we knew the centricity was purely stud/lug based, or if it was both:

1) Lug centric for rotational purposes only?

2) Hub centric for load?

3) Both?

4) Lug centric for load completely?

I don't want to end up with a mess on my hands (nor would anyone) So at this point, i either need to know for sure what i need to care about re centricity, or what i don't need to care about :)

I also think i might have a stud length issue to grind off :( 1.25 inch studs and unlikely i have a quarter inch hollow in the stock steel wheels to accept that after 1 inch spacers are affixed.

02-08 Sport trac info Should be able to scroll down just a slight bit and see where it says Go to matching vehicles then scroll down until you see Ford Ranger listings. You'll find all the same Hub bore sizes as well as stud and other great information for comparison purposes.

Load bearing is stud specific and ANY lug-centric wheel used will be as such and the hub becomes more of a lazy tire guys locator pin and nothing much more on the Ranger. Not quite sure I understand the second part of that question about the "whilst the hug is there and relatively tight to the stock wheels at least, there is no load on it".

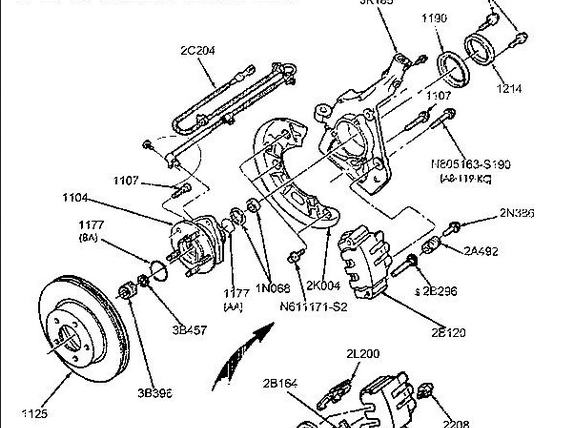

As you can see in this 98+ assembly breakdown, the spindle (2wd ONLY) bolts to the steering knuckle, the 2WD hub assembly rides the spindle and is shimmed by seals and bearings both sides while a washer and a castle nut hold it in place. The hub assembly houses the lugs which pass through a rotor loosely and when the wheel is brought into the picture it acts as a clamp for the rotor which also centers itself on a widened shoulder of the studs in some cases much like the lugs centering themselves in the beveled edges of the wheels lug holes completing the unit. as far as where the load is, I am not sure I know how to answer that just yet. To me, I would presume the load is ideally on the spindle as that's where the bearings are located and kept lubricated.

As far as a response to your questions:

- Yes

- No

- No

- and Yes

Absolutely, I am just hoping I did not make it further confusing for you or anyone else. I think until we see something taken apart and had done that ourselves. Sometimes it is difficult to prevent the brain from over analyzing something until we do it once or twice. Like they say, sometimes you have to get your hands into it.

You may.. What I would do is when you get your spacers whether through us or otherwise. Generally you could take the time to replace each one with shorter studs available at most affluent auto-parts stores, maybe even a tire shop.

OR

Mount one spacer with two open ended lugs and take note of the depth of the lug on the threads and the spacers edge. Then I would thread all open ended lugs onto the studs, cut where needed, use the lug nuts to clean thread pitches and reassemble as needed.

Our suggestion would of course take the extra step to replacing the studs and/or consider 1.25" spacers to save time and headaches if clearances allow for it. Just a thought there.

____________________

North Industries

Las Vegas, Nevada 89118

Web http://www.12degnorth.com

|