410customs

Idahome

Joined: Wed May 2nd, 2018

Posts: 2165

Name: Jamie ... Occupation: Elevator Design Worlds Tallest Buildings ... Interests: Ranger Based Vehicles and OFFROAD ...

Reputation Points: 2165

|

So working through the short list of things to fix before she can go home.

#1, slight coolant leak from the coolant line mounted on pass side of the lower intake manifold. The fitting was simply not tight enough. This is pretty common.

Lucky for me I have fixed this same issue a time or two and I know that you can slide a 1" wrench in there if you are careful. So just had to remove the 3 nuts holding the coil pack tripod down and wiggle my way with the wrench to tighten it up. Tighten 1/8 of a turn, flip wrench over, tighten....repeat until its fully tight in the intake

hard to see but the wrench is on the fitting in this pic

see the puddle of red coolant? NO MORE!

NO LEAKS ALLOWED!! that Amsoil red coolant is nasty when it leaks and gets cooked in place. I had to do a little cleaning to make it easy to spot if it returns.

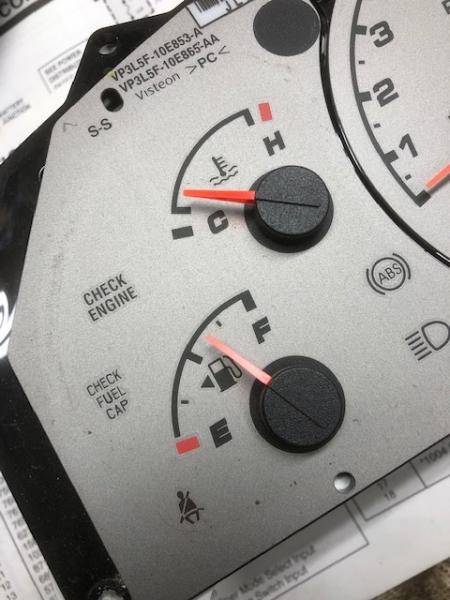

#2 Next up, the instrument cluster coolant gauge was INOP, earlier in the thread we tried a new sensor and I suspected it was not the correct part...it was not. So I simply removed it with a 19mm deep socket while the coil pack was loose and replaced it with a stock 98 95.0 coolant sensor.

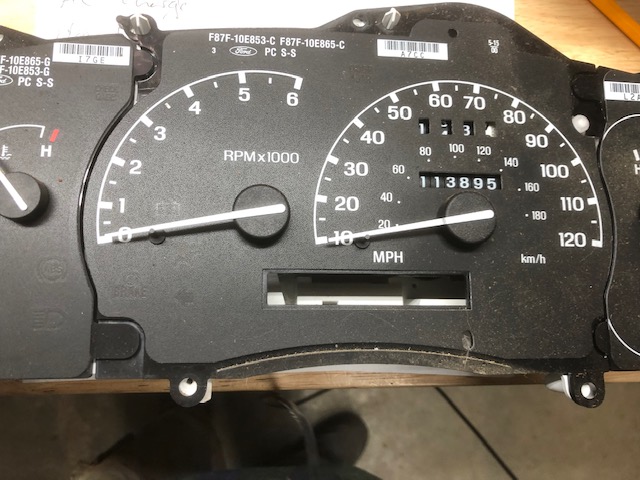

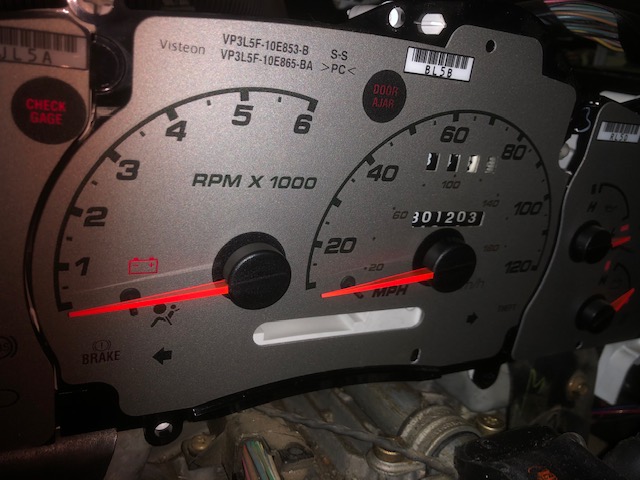

#3 the tachometer was hanging, most times it was reading correctly for the new V8 but it would stick at 3000-2500 rpm. I know this issue I have seen it many times before, with these miles the tachometer head is simply worn out. So I removed the cluster and replaced it with another tachometer head from a 2000 explorer with only 113K on the clock. While the cluster is out it also gets a thorough cleaning (just water and elbow grease)

Cluster is put on the bench and dismantled

with the clear plastic removed we can see the buildup of dirt/soil/smudges

First thing to do is remove the needle from the tachometer so the needle is not attached to the head/drive. A fork is the perfect tool for this, carefully pry and pull upward

I also removed the speedometer needle, I did not have too...whoops. No harm no foul

113K cluster for parts

There are 3 "modules" that make up your instrument cluster, they simply pull straight up and out. The first two outer modules must come off first then you can pull up and out the center module containing the speedo and tachometer

Flip the center module over to reveal the two screws that hold the tachometer drive to the cluster

Compare the parts, make SURE they are the same unit

Sure enough the old 301K unit has a nice rattle inside, much "looseness" the part is BAD

Replace with the new one and put the cluster back together

This time I use a clean towel and filtered water to wipe down the gauge faces

Also water, Q tips and towel are used to clean the inside of the cluster "glass"

Cluster is put back together....BUT DO NOT SEAT THE NEEDLES YET or install the glass

the cluster MUST be hooked to the trucks power and the truck turned on, so the cluster is powered NOW you can CAREFULLY put the needles into their home position (resting on the pegs)

See how clean the surfaces are now? no more schmutz

Cluster now put back on the bench and all screws put back in, ready for re install

Done, moving on

#4, Lazy 4x4 shift. So this truck is still using the Ranger shift motor on the transfer case and I was unable to get the low range shift. Truck in N, foot on brake, no low shift. 4 high was also taking a while. I know this is a lazy shift motor so I decided to remove it and give it a soft rebuild.

Shift MOTOR (LOL!!) placed on the bench and taken apart. First mark the stator housing so you can be sure to put it back together in the exact same position. Looks to be 301K miles inside, plenty of dirt and grime.

nasty look at the stator, it is not supposed to be black!

rouge on the stator gear shaft also

Nasty brushes too

Parts will all be cleaned up

scotch brite, sandpaper and PB blaster are all that is needed, and some Q tips.

way better

everything is clean, the stator, the brushes, housing, bushings, gears, and case.

Now to re assemble, I use some white grease on the rotating bits and some anti seize on the plastic bushing.

Clean brushes are now seated on their springs and using the little tabs in the plastic the wires can hold them back so you can insert the rotor...nice of Ford to do this, the older motors DID not have this.

With the rotor in place the brush wires are released, now you can CAREFULLY install the case/magnets. Holding the worm drive in place makes things go together easily.

Motor is re installed on the truck and the 4x4 shift is checked.

WOW what an improvement, I can hear the motor shift and the shift relays click behind the dash. 2wd to 4 high is VASTLY improved. It was taking 2-3 seconds to shift... not anymore

However still no LOW RANGE. Lucky for me I know EXACTLY where to look

#5, no low range

Okay so this one is a bit tricky and has stumped many people over the years. Lucky for me we have run into this a few times before. You see in order for the truck to allow the shift from 4hi to 4 low you must be stopped and in N. So how does the truck know you are stopped? signal from the VSS to the gem module of course. How does it know you have your foot on the brake? Signal from the BPP (brake pedal pos) switch to the GEM module of course. How does it know you are in Neutral...well there is a wire that feeds the GEM module directly from the neutral safety switch on the side of the transmission. Also known as the DTRS (digital transmission range sensor). So what gives?

Well the 5.0 explorers never had electronic shift controls, they were all either RWD or full time AWD> no 4x4. So Ford for whatever reason left this one wire out ONLY ON SOME TRUCKS! The crazy thing is the wire is shown as existing in all of the wiring books. However when we go to check we can see, sure enough although the wire exists on the truck side of things it is MIA on the 5.0 engine/trans harness.

Pin 33 is Red/White circuit 463, NSS (neutral safety sensor) from trans DTRS through the 42 pin connector to the truck

Fuzzy but you can see pin 33 is MIA on the engine side

I drilled out the blank spot

Now I need a wire, the best thing to do is use the SAME wire from the old 4.0 harness

This guy is carefully removed from the old harness

from 42 pin plug to transmission DTRS unpinned on both sides and pulled out

Now to install on truck/5.0 harness

It was late Sunday night so I decided to stop here. But before I could sleep I had to know, did it work? I know that the NSS signal is simply a ground (when in Neutral the transmission sends ground through this wire) so I placed it on the - battery terminal, put truck in N and with foot on the brake without hesitation the truck EASILY shifted into LOW RANGE!!

Success!! Today I will properly route the wire and install in the v8 DTRS harness.

Slept like a baby

List of things to fix is now very very short, as in I just need to adjust the front alignment / toe, that will happen this am

____________________

I build custom RBV, specializing in drivetrain conversions, wiring, suspension and complete custom trucks

|

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6

1 2 3 4 5 6